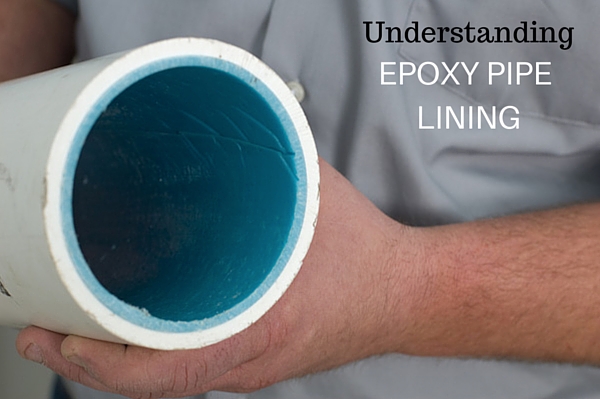

Understanding Epoxy Pipe Lining

Epoxy pipe lining is one of the most popular methods for trenchless sewer and pipe replacement nowadays. Before you decide which trenchless plumbing method is best for you, though, you should ensure that you fully understand what each process entails. Pipe lining is considered a cost effective alternative to traditional plumbing methods that require you to dig up the landscaping around the plumbing.

Cured-in-Place Piping

The technical name used for epoxy pipe lining is cured-in-place piping. This process is termed such because, as its name implies, the piping is cured in place during this method. It is basically like getting a new flow in your current pipe without having to remove the old piping. It provides you with the structural strength of a new pipe without being as invasive or environmentally harmful as traditional “dig and trench” methods.

Evaluation

The first step of implementing epoxy pipe lining is to conduct an evaluation of the existing pipes to determine if this method of plumbing would be a feasible option. Some ways that evaluation is conducted is by using video sewer cameras to determine exactly what needs to be done to resolve the issues with the plumbing as well as to assess whether the current pimping meets the requirement to accept a cured-in-place pipe.

Preparation

If it’s determined that it’s okay to move forward with epoxy piping, then the preparation process start. Before it can be run through your existing pipes, the existing pipes must be cleaned. A high pressure water jet sprayer and other specialized tools help remove fat, oil, grease, dirt, mud, tree roots and other debris from the inside of the existing pipes.

Placing the Epoxy Liner

Finally, once all the prep work has been done, the new epoxy liner can be placed. This is accomplished by running lines that have been soaked in resin through the damaged pipelines. The two-part epoxy resin cures in place, and this creates a structural bond between the old pipe and the new lining without having to move any of the soil around the piping. Everything is left intact, but you essentially receive a new flow through your existing piping without disturbing the ground’s surface.

The New “Pipe Within a Pipe”

The final product leaves you with a “pipe within a pipe” that offers you a seamless piping unit that can’t be permeating by tree roots like the previous pipe could. This is because the new piping is joint less, so there is nowhere for the roots to come through. Additionally, you’ll no longer have to worry about calcification since calcium deposits won’t be able to adhere to the inner walls of the epoxy barrier-lined pipe.

No matter whether you have piping that runs vertically or horizontally, epoxy pipe lining is a possible option. If one of your main concerns is repairing your piping system without disturbing your landscape or destroying any architecture, then this just might be the type of plumbing solution that you need.